Table 2: Model Number Suffix Letter Designation

Model No. Ambient Temperature Pressure Regulator

Suffix Letter Range Type

H 0°F to +175°F (-18°C to +79°C) Slow-opening

K -40°F to +175°F (-40°C to +79°C) –

M -40°F to +175°F (-40°C to +79°C) Standard

N 0°F to +175°F (-18°C to +79°C) Two-stage slow-

opening

P -40°F to +175°F (-40°C to +79°C) Step-opening

Q -40°F to +175°F (-40°C to +79°C) Two-stage standard

S (SV9510, -40°F to +175°F (-40°C to +79°C) Standard

SV9520 only)

Line voltage polarity sensing models monitor the

line voltage input connection to assure line voltage

polarity is correct. If line voltage polarity is incorrect,

the LED diagnosis code will flash and the control will

not respond to the call for heat. These models also

provide added LED diagnostic codes (“6+”) to indicate

the reason the control has moved to the lockout state.

Depending on models, various timings are available,

such as 15 or 30 seconds pre-purge; post-purge

five seconds (typical depending on model; this is

not available when the SmartValve™ is connected

directly to the thermostat); five, seven or nine seconds

trial for ignition; 60-minute soft lockout; three retries;

four trials before lockout. The other unusual feature

is that the draft inducer is now controlled from the

SmartValve™; depending on the version, this is accomplished

by either interrupting the 120 volts or

24-volt signal. This will be defined as each diagram is

discussed.

The capacities on SV9510, 20 and 40½" x ½"

200,000 BTUs maximum and on the SV9610, 20,

40¾" x ¾" is 415,000 BTUs.

Figure 1 is an illustration of the top view of the

valves. The C3 connector is for 120-volt power, and this

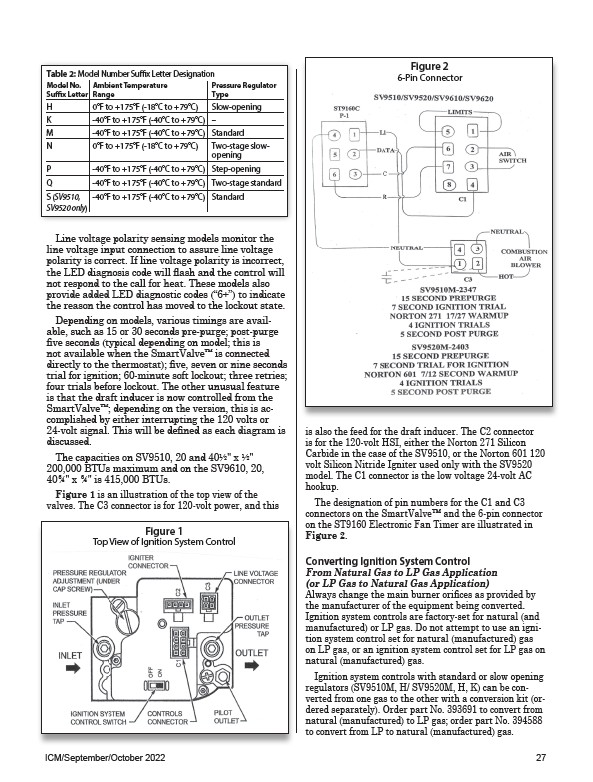

Figure 2

6-Pin Connector

is also the feed for the draft inducer. The C2 connector

is for the 120-volt HSI, either the Norton 271 Silicon

Carbide in the case of the SV9510, or the Norton 601 120

volt Silicon Nitride Igniter used only with the SV9520

model. The C1 connector is the low voltage 24-volt AC

hookup.

The designation of pin numbers for the C1 and C3

connectors on the SmartValve™ and the 6-pin connector

on the ST9160 Electronic Fan Timer are illustrated in

Figure 2.

Converting Ignition System Control

From Natural Gas to LP Gas Application

(or LP Gas to Natural Gas Application)

Always change the main burner orifices as provided by

the manufacturer of the equipment being converted.

Ignition system controls are factory-set for natural (and

manufactured) or LP gas. Do not attempt to use an ignition

system control set for natural (manufactured) gas

on LP gas, or an ignition system control set for LP gas on

natural (manufactured) gas.

Ignition system controls with standard or slow opening

regulators (SV9510M, H/ SV9520M, H, K) can be converted

from one gas to the other with a conversion kit (ordered

separately). Order part No. 393691 to convert from

natural (manufactured) to LP gas; order part No. 394588

to convert from LP to natural (manufactured) gas.

Figure 1

Top View of Ignition System Control

ICM/September/October 2022 27